Working processes

Design

Our products are parts made to our customers' designs. The part design and planning stage is therefore handled by our customers themselves, who provide us with the specifications required to manufacture the parts. Compliance with their parameters is handled using cutting-edge technology to ensure total customer satisfaction.

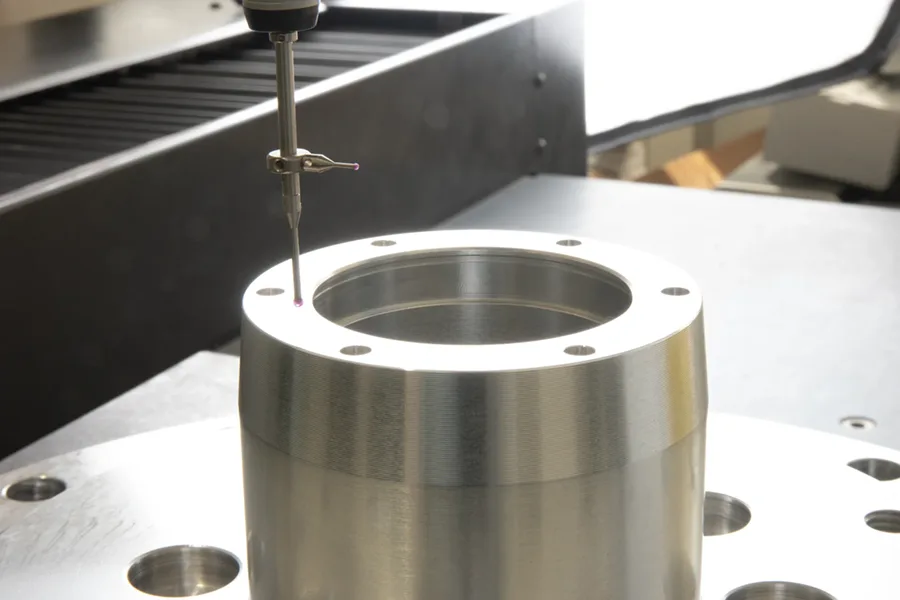

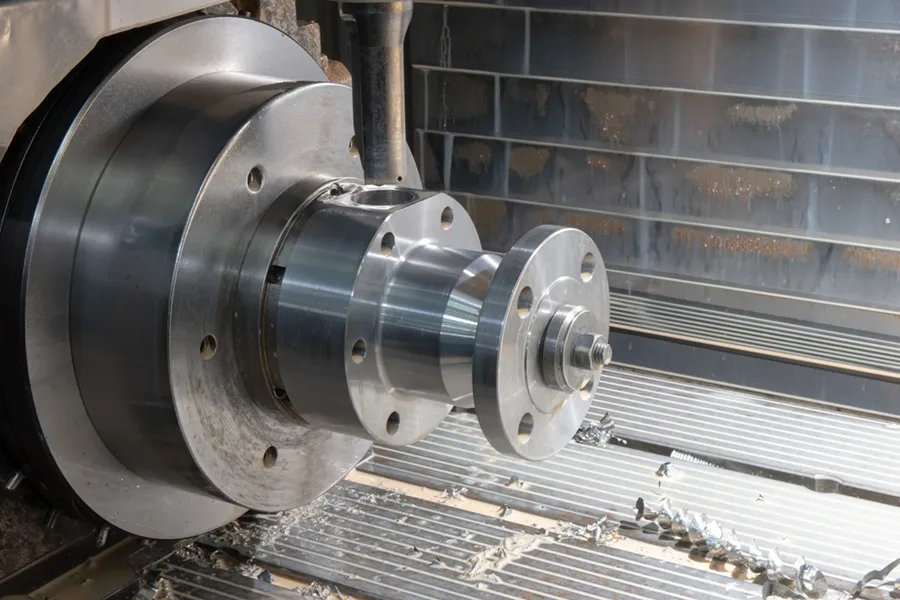

Machining

We specialize in the manufacture of reducers and casing for medium and large sized industrial gas installations and industrial valves. We carry out in-house turning and milling with CNC machines and are able to provide various services such as grinding, anodizing, zinc and chrome plating, burnishing, hardening and tempering, through a chain of specialized suppliers. We regularly machine ASTM 350 LF2 and ASTM 105 bars and pressed parts, as well as materials requested by customers.

Management

We handle all supply stages as the "prime contractor" from raw material procurement to the finished product. We ensure the traceability of the materials purchased and provide any documentation customers require according to their needs. Most of our products are destined for the world market and we ship mainly to European countries.